Looking for a reliable

3D Scanning Service

provider for your Plant and Tank Survey?

Look no further! Get high-precision scans with reliable 3D Laser Scanning services.

To get complete details and quote

about the testing technique

CONTACT US NOW!

Did you know?

- Over 60% of ageing plants lack design drawings, resulting in a lack of traceability for critical locations.

- The absence of these drawings poses challenges in inspection planning and defining work scopes due to data unavailability.

- Relying on outdated or inaccurate 2D drawings during maintenance or upgrades poses risks.

- This reliance often leads to misinterpretations, causing errors and delays in project execution.

- The unavailability of digital 3D models hampers effective planning for modifications or expansions.

- The lack of comprehensive 3D models and drawings restricts efficient facility management, making tasks like identifying layouts and implementing safety measures challenging.

- Troubleshooting operational issues becomes difficult without detailed drawings and 3D models, leading to prolonged downtime and increased operational costs.

- Ensuring compliance with industry regulations becomes arduous without accurate documentation, potentially resulting in difficulties during audits or inspections.

- Without comprehensive tank survey services, undetected leaks or structural weaknesses pose severe environmental risks, potentially leading to soil contamination or hazardous substance spills

- Lack of precise tank survey might result in undetected structural flaws or corrosion, compromising the tank’s structural integrity, and increasing the likelihood of failures or leaks.

- Without efficient survey methods like 3D scanning, inspections become time-consuming, leading to extended downtimes during maintenance or assessments, impacting operational productivity

- Insufficient or infrequent inspections may lead to unexpected issues or failures, necessitating costly emergency repairs or replacements, substantially impacting operational budgets

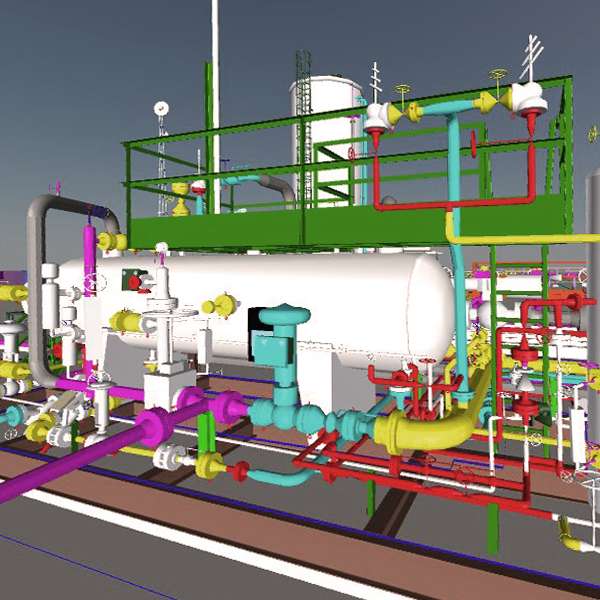

At IRC Engineering, we understand the critical challenges you face in plant and tank management. With our state-of-the-art 3D scanning services, we offer tailored solutions to these complex issues

- We create detailed 3D models and drawings, ensuring traceability and simplifying inspection planning.

- Our advanced 3D laser scanning services transform outdated 2D drawings into accurate, digital models, reducing errors and project delays.

- We provide comprehensive 3D documentation, aiding in troubleshooting, reducing downtime, and ensuring regulatory compliance.

- Our precise tank surveys detect potential leaks and structural weaknesses, safeguarding against environmental hazards.

- Our efficient 3D scanning techniques minimize maintenance downtimes and prevent costly emergencies.

Choose IRC Engineering for reliable, cost-effective, and innovative 3D scanning solutions, turning industry challenges into opportunities for growth and efficiency.

IRC has over 25 Years of Experience in

the Industry Providing Quality Services

At IRC Engineering Services India Pvt. Ltd., we specialize in digitizing assets through 3D models and as-built drawings using cutting-edge 3D laser scanning technology

Advanced 3D Scanning Technology

IRC Engineering

uses cutting-edge technology for accurate 3D model generation, tailored for various energy sectors, ensuring precision and efficiency.

Interactive Data Visulisation

Our web-based 3D viewer offers quick analytics and reporting, enhancing asset management and decision-making capabilities.

Accurate Tank Surverys

We deliver detailed geometry information, as-built 3D models, and precise measurements for tanks, aiding in thorough evaluations and maintenance planning.

Customized Plant Solutions

We provide industry-specific solutions, optimizing workflows in the power, oil & gas, and hydro sectors.

Operational Excellence

Our techniques streamline operations, reducing project timelines and costs, complemented by comprehensive reporting for informed decision-making.

Seamless Integration

Our non-disruptive 3D scanning implementation ensures uninterrupted plant operations.

Why Choose Our 3D Scanning Services?

At IRC Engineering, we don’t just provide a service; we create an experience. Choose us for:

Cutting-Edge Technology

Our 3D scanners utilise the latest advancements for unmatched precision.

Collaborative Approach

Partner with us for a seamless journey from concept to reality.

Tailored Solutions

Your project is unique; our solutions are tailored to match.

Elevate your vision with us. Choose excellence.

Our Other Services at IRC Engineering

1350 Boilers

100 Turbines

50 Generators

Residual Life Assessment

50,000 Tubes

PAUT of Boiler Tubes Inspected in a Year

300 Projects and

3010 shutdowns

NDT Services

1000 Tanks

1500 KM Pipeline

Fitness for service assessment

8 Machines

Phased Array Ultrasonic Testing/ Time of Flight Diffraction Inspection service

Lakhs of

Samples

Tensile Testing / Impact Testing / Spectro Testing

14,600 hours on

Rope

IRATA Rope Access Services

700 Samples

Failure Investigation

3 Machines

Pulsed Eddycurrent Testing

2 Machines

Long Range Ultrasonic Testing

3 Machines

Helium Leak Detection

Get complete details and quote about the testing techniques