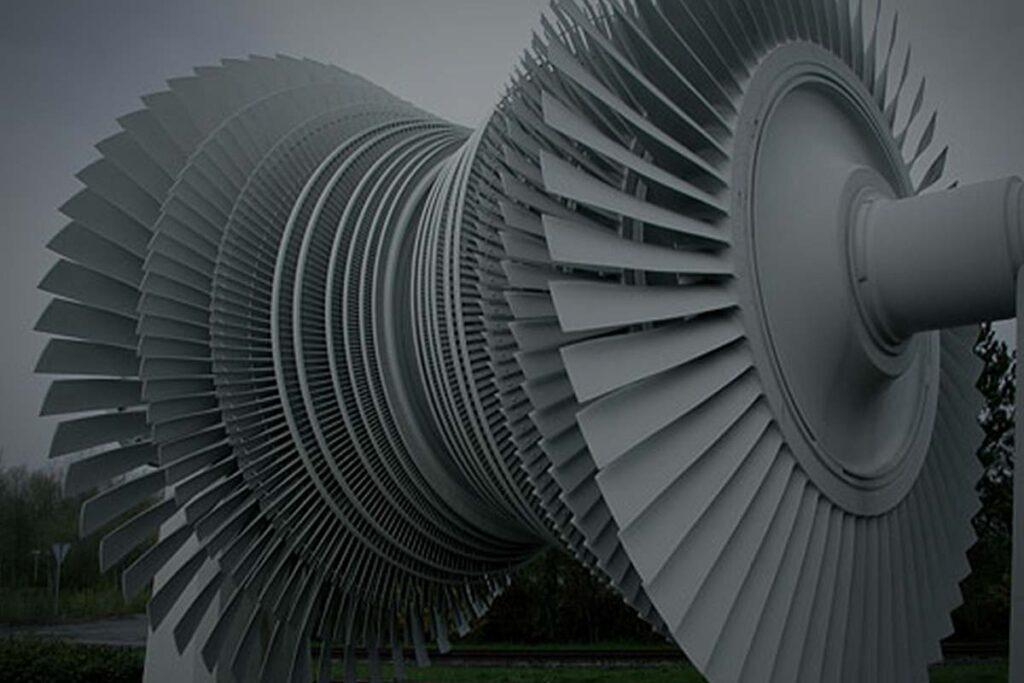

IRC Engineering Services has been carrying out Residual Life Assessment of Turbines since 10 years now. Our team of Turbine experts comprises of Ex NTPC & BHEL GMs and AGMs. With there technical expertise in the field of , turbines and generators IRC has evolved as a market leader in the field. Our supporting team responsible for conducting Non- Destructive Testing for Residual Life Assessment are specialists having ASNT NDT Level II and ASNT NDT Level-III certification.

Why do we need to carry out Residual Life Assessment of Turbine?

Due to escalating cost of new capacity addition , long lead time, and stringent environmental regulatory restraints for new installations, it is very to set-up new units . Case studies have shown that by initiating timely preventive measures of proper maintenance / refurbishment , it is possible to extend the life cycle of turbines for another 15 to 20 years . In view of the economic and planning advantages, life extension of existing power plants has gained increasing importance throughout the world. With the aid of modern technology in the field of residual life assessment , it is now considered feasible to extend the life of plants beyond 100,000 equivalent operating hours by limited investment.

Here are some advantages of carrying out residual life assessment of turbines:

- To prevent the catastrophic failure like bursting of rotors.

- To enhance the operating life of the turbine.

- To prevent unscheduled outages.

- To avoid unnecessary repairs.

- To plan for replacement of selected com

- To stock necessary spares in advance.

- To increase operational reliability of the set.

- To increase thermal efficiency by operational changes or equipment modification.

Residual life assessment of turbines requires data collection accompanied by results of Non destructive tests.

Collection of back ground information like the capacity of the plant, process involved in the generation of power , running hours etc..

Performance & operational data in terms of availability, heat rate, rise of steam pressure at curt ice wheel, vibration , differential & total expansion and data regarding temperature difference between top & bottom casing of turbine, are the inputs required to focus attention of study team.

After the collection of the data following tests are performed for residual life assessment:

- Visual examination

- Dye Penetration Test (DPT)

- Magnetic Particle Inspection (MPI)

- Eddycurrent testing

- Borosonic Test

- Hardness Test

- In situ metallographic examination by replica technique

- Natural Frequency Test

Steam Path Audit

IRC Engineering Services is one of the few in the industry who carry out services for steam path audit. IRC has an specialized software to evaluate loss of heat energy and loss of output in terms of Kwhrs. accrued over a service life of turbine in the past . Impact of drift in original configuration of blades due to abrasion or change of clearances is also evaluated by such audit.

IRC is privileged to have served few utilities of repute by offering such specialized service.

IRC Engineering Services

IRC Engineering Services