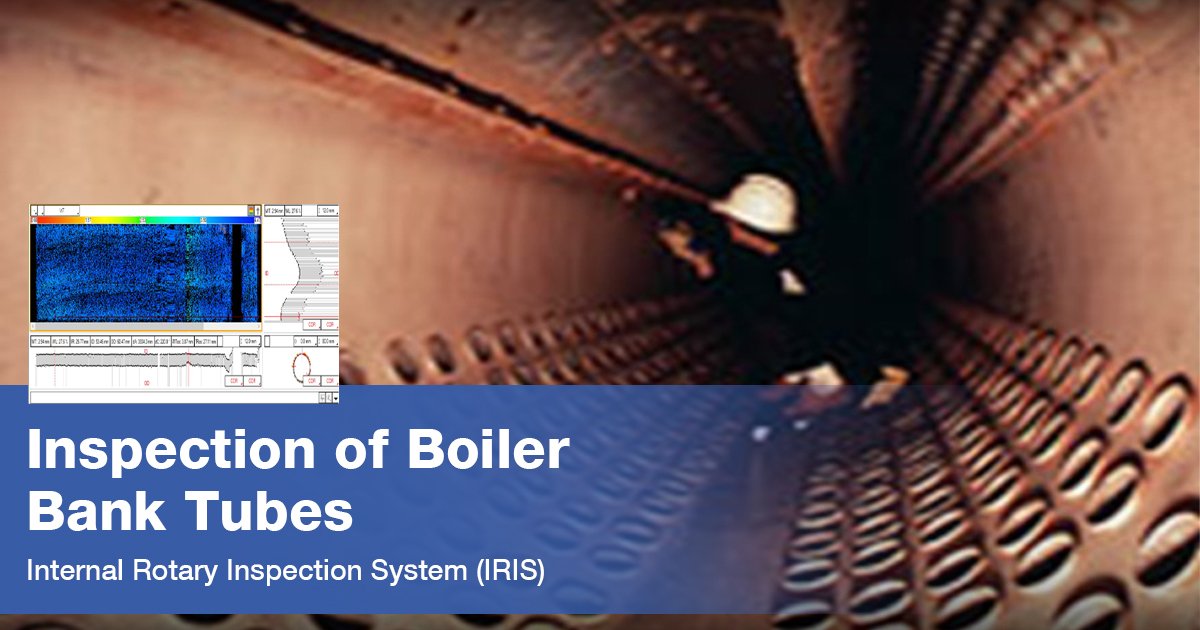

Are you unable to carry out the Inspection of Boiler Bank tubes?

Are you regularly carrying out Capital Investment by purchasing tubes rather than finding only the defective Bank Tubes?

Here is the solution for inspection of Boiler Bank Tubes –

In case of Boiler Bank Tubes, only the Front Column of Tubes are available for Inspection for Thickness Testing externally there is no other way to check the rest of the Tubes. Thus we have only 5 % of the Tubes available while we miss out on an inspection of the rest of the 95% of the tubes.

RFET was done previously to ascertain the condition of the rest of the 95% of the tubes but due to the limitation of the technique it is also not a right testing method. Then we tried IRIS on these tubes and got amazing results.

HOW IT WORKS –

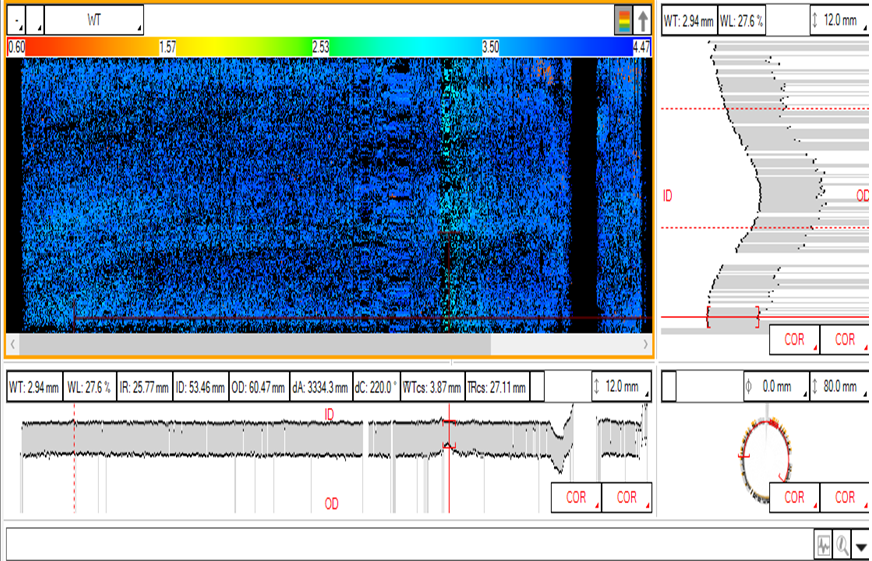

Because IRIS is an ultrasonic technique, it requires a couplant. In this case, water. Tubes under test must therefore first be flooded to use this technique. IRIS relies on a transducer to generate an ultrasonic pulse parallel to the axis of the tube under test. It also relies on a rotating mirror that directs the ultrasonic wave into the tube wall.

The mirror is driven by a small turbine powered by the pressure of water pumped into the tube. Part of the ultrasonic wave is reflected by the inner diameter (ID) wall, while the rest is reflected by the outer diameter (OD) wall of the tube. Because the ultrasonic velocity of the tube’s material is known, it is possible to assess the thickness of the wall by calculating the difference in times of flight between the two diameters. As the probe is pulled, the spinning motion of the mirror results in a helical scan path.

A critical aspect of IRIS is ensuring that the mirror is at the centre of the tube. An off-centre ultrasonic pulse yields a distorted scan image because of the different ID and OD wall sound paths. That’s why our IRIS kits are equipped with centring devices helping operators keep the system centred.

About IRC Engineering Pvt. Ltd.

IRC is one of the fastest growing Testing and Inspection company in India. We at IRC provide Liquid Penetrant Testing, Non-Destructive Testing, Destructive Testing, Advanced NDT, Third Party Inspection, Condenser Testing, Electrical Testing, Residual Life Assessment of Power Plant, O&M Services, Fitness For Service, Civil Testing and Training services.

IRC Engineering Services

IRC Engineering Services

Join the conversation