Unplanned outages in power plants are not just minor discomfort – they are financial and operating nightmares. One of the main causes of these unexpected shutdowns is the failure of the boiler water tubes due to Corrosion, deposits, thinning, Hydrogen Damage, etc. If these issues are not addressed to anyone, they can give rise to failures, forcing power plants to close for extensive repair, and losing millions in lost revenue and operational downtime.

But what if we can find out these problems before they become critical? This is where robotic thickness mapping comes in. This advanced non-destructive test (NDT) technique, which is integrated with the robot platform, enables real-time monitoring at early stages of the detection in water wall tubes. This allows power plants to operate active maintenance, avoid expensive breakdowns, and ensure uninterrupted energy production.

Hidden Cost Of Unplanned Outages in Power Generation

Power plants are high-revenue operations that require continuous uptime. Any unplanned shutdown means immediate financial loss, security concerns, and disruption in maintenance.

The financial impact of downtime

- Unplanned outages are costly: Unexpected plant shutdowns suspend production and require immediate repairs. Unplanned outages cost as much as $2 million an hour, directly impacting operational costs and profitability.

- Emergency repair is more expensive: Spontaneous equipment breakdown tends to necessitate immediate repair, such as expensive part replacement, overtime compensation, and fixes. These unscheduled maintenance activities are much costlier compared to scheduled maintenance activities.

- Disruption in energy supply invites punishment: Power plants have to fulfill supply contracts with power grids. Defaulting on the delivery of energy as contracted can lead to substantial financial penalties, damaging both revenues and business relations.

- Insurance and liability issues: Recurring equipment breakdowns imply inadequate maintenance, which means higher insurance rates and possible legal troubles. This increases operating expenses and subjects the company to more financial and reputational risk.

The Risk of Undetected Corrosion in Water Wall Tubes

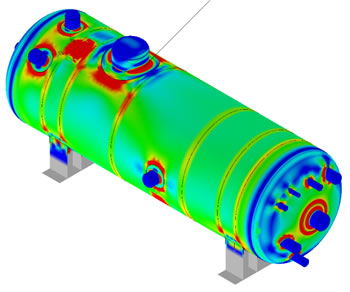

The water wall tubes are brought in contact with high temperatures, high pressure and combustion gases, making them susceptible for rust and thinning.

- Corrosion weakens the walls of the tube, which increases the risk of rupture and failure.

- Sudden failure can cause boiler explosions, force emergency shutdowns and workers can cause safety threats.

How Robotic Thickness Mapping Works

Robotic thickness mapping is a revolutionary non-destructive test (NDT) method that allows engineers to monitor the tube health status without closing the plant.

How it works:

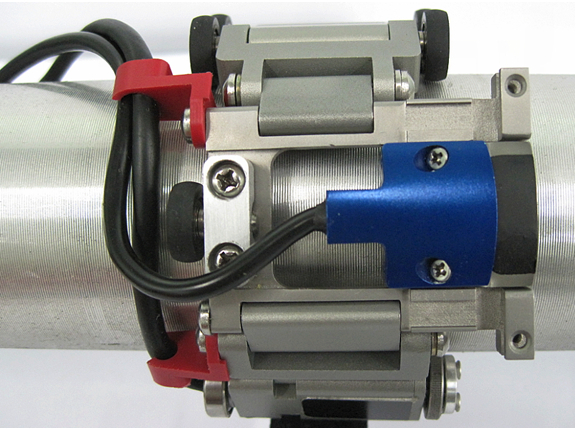

- Robotic Crawlers: Robots equipped with magnetic wheels and having multiple sensors attached for continuous NDT inspection of tubes

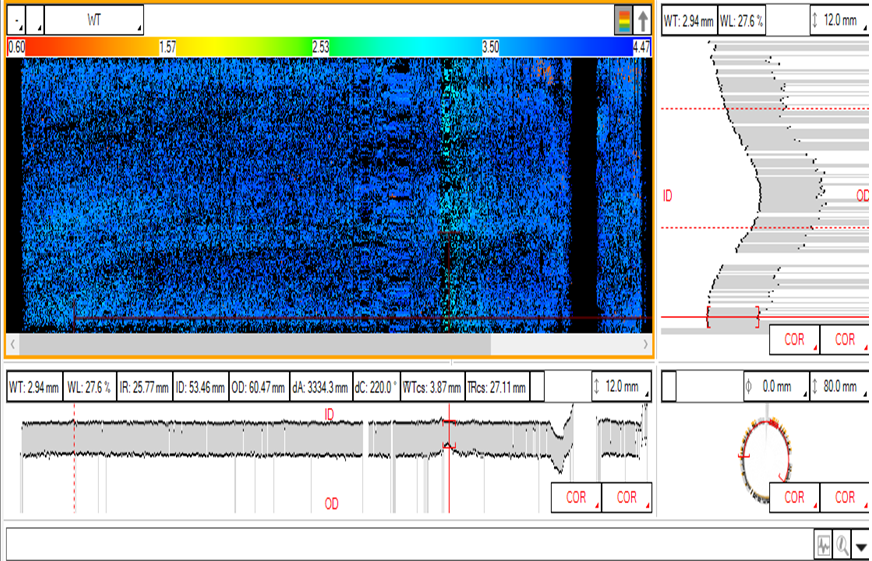

- NDT Sensor: Various advanced sensors ( RFET, UT) measure the thickness of the wall, corrosion levels, and cracks.

- Real-time Data Collection: Robot transmission transmits live data, allowing immediate analysis.

- Predictive Analytics: AI-operated software analyzes historical thickness data to predict potential failures.

- No Scuffolding is required: unlike traditional inspections, robot mapping is performed, while the plant remains on, avoiding unnecessary downtime.

Example: Robot

- A magnetic crawler robot that climbs the walls of the vertical boiler eliminates the need for scaffolding.

- Real-time uses a high-resolution ultrasonic test (UT) to detect a minute thickness variation.

- Power plants help plan targeted maintenance rather than unnecessary full-scale inspection.

With robotic thickness mapping, power plants can take action before failures, ensuring smooth operation and extended tools.

Limits of Traditional Inspection Methods

Robotic thickness provides rapid, safe, and more accurate inspection than manual methods.

Limits of Traditional Inspections:

- Time Consuming – Week preparation: Traditional methods of inspection require a lot of setup time, sometimes taking days or even a week. This means creating scaffolding, setting safety gear, and testing areas, resulting in major delays before any work on inspection gets underway.

- High-risk for workers: Inspectors have to physically ascend high and intricate boiler structures to carry out manual inspections. This subjects them to severe risks like falls, heat stress, and confined spaces, making the work extremely dangerous and accident-prone.

- Limited accuracy: Manual ultrasonic testing relies considerably on the ability and judgment of the inspector, wherein we are checking the thickness only in localized area rather than mapping the tube , because of which we are highly likely to miss out on defects.

Why robotic inspections are better:

- 10x faster: Robot inspections significantly cut down on time by scanning enormous areas in no time. Compared to human teams, which could take days, robots accomplish the same task within hours, cutting down on time and reducing downtime, which is important for time-critical industrial processes.

- Discovers sub-millimeter flaws: Sophisticated robotic sensors are very sensitive and can detect even sub-millimeter thickness variations in material. These small defects usually escape manual inspection but may indicate initial-stage corrosion or damage, enabling preemptive maintenance to avoid larger, more expensive failures.

- Works in difficult-to-reach areas: Robots are made to reach hard-to-access areas l

- Protects workers: Robotic inspections eliminate the necessity for human entry into high-risk areas such as high-temperature or toxic environments. This reduces exposure to dangerous conditions, significantly enhancing worker safety and adhering to stringent occupational health and safety guidelines in industries.

Financial Savings To Prevent Detection

Case study: How a power plant saved $ 2M per hour

- A thermal power plant applied robotic thickness mapping to detect early hydrogen damage in water wall tubes.

- By changing the damaged tubes before the failure, he avoided a forced shutdown, which could cost $ 2 million per hour.

- This preventive approach saved millions in emergency repairs and saved expensive punishment.

ROI of robotic inspections

- Cost of low maintenance – initial identity reduces the requirement for emergency repair.

- Extended Equipment Life – Active Monitoring prevents premature tube failure.

- Low insurance premium – Low accidents and failures mean low liability risk.

Frequently Asked Questions

What is the robotic thickness mapping of water wall tubes?

This is an advanced inspection method using a robot system equipped with a non-destructive test (NDT) sensor such as UT/RFET to measure the thickness of water wall tubes and detect early signals of corrosion or damage.

How does robotic thickness mapping stop unplanned outages?

By identifying the initial stage of rust and thinning, robot inspections allow for timely maintenance and reduce the risk of unexpected tube failures and expensive shutdowns.

What are the advantages of robot inspection over manual methods?

Robotic inspections are 10x sharp, sub-millimeters provide accuracy, reduces shutdown duration, maps the entire Boiler Tube rather than in some points only and workers improve safety by reducing dangerous manual inspections.

Which industries benefit from robotic thickness mapping?

Power plants, oil and gas, water utilities, and chemical industries use this technique to expand asset life, improve efficiency, and reduce downtime.

What is the future of robotic thickness mapping?

AI-powered predictive analytics, hybrid robotic systems, and fully autonomous inspection robots will make industrial maintenance smarter, faster, and more cost-effective.

read more IRC Engineering Services

IRC Engineering Services